RDC + Robotic Pick-and-Place (PnP)

When integrated with a rotary die cutting (RDC) machine, robotic arms are primarily used for key processes such as material loading and unloading, waste sorting, and finished product palletizing. This solution is suitable for multiple industries that rely on rotary die cutting, including electronics, packaging, and medical applications. It delivers significant benefits, including improved efficiency, reduced labor costs, and enhanced product quality.

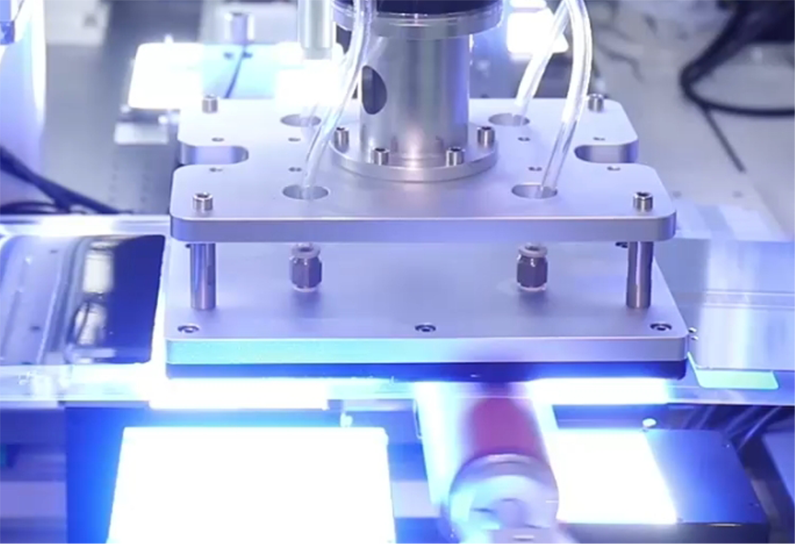

Automatic loading and unloading

RDC machines are widely used in continuous production. Robotic systems ensure consistent material feeding and efficient transfer of semi-finished products. In electronics applications, robots accurately feed roll materials into the RDC machine and move processed parts to the next station, reducing manual handling, preventing line interruptions, and improving equipment utilization.

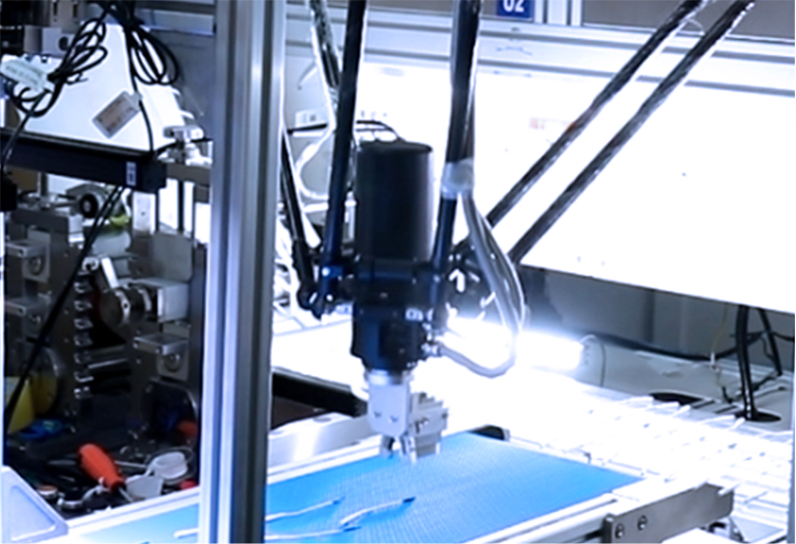

Finished product sorting and palletizing

Finished products such as medical dressings, electronic pads, and packaging labels are automatically sorted and palletized by robotic systems. Products are accurately picked, stacked to specification, and automatically counted, enabling standardized handling for downstream warehousing and quality inspection while eliminating manual errors.

Key Features

- Higher Efficiency & Stability: 24/7 operation with multi-axis control, maintaining high precision at speeds up to 60 m/min and boosting productivity by ~30%.

- Consistent Precision & Quality through programmable, repeatable positioning.

- Lower Operating Costs and Enhanced Safety.

- Flexible Production Adaptability.

*HOACO can customize the mechanical hands you need according to your requirements.