RDC+FLATBED CUTTING DIE MACHINE

RDC + Flatbed Die Cutting

By combining rotary and flatbed die cutting, this solution delivers continuous high efficiency with high precision and complex cutting capability. It supports both high-volume production and demanding applications across multiple industries.

Advantages

Unlimited Material Compatibility

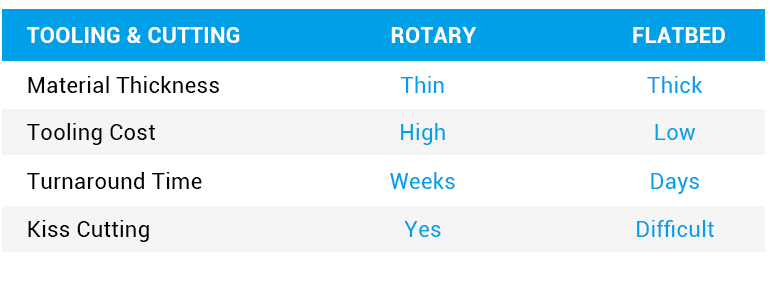

Rotary die cutting advantages: Excels in continuous processing of thin, soft, roll-fed materials such as PET films, copper/aluminum foils, adhesive labels, and nonwovens. It handles elastic and adhesive materials without the risk of stretching or deformation. Flatbed die cutting advantages: Designed for precise cutting of thick, rigid, or sheet materials—including foam, rubber, cardboard, metal sheets, and rigid PCBs. Its robust structure withstands high cutting forces, ensuring stable and accurate processing.

Reduced Changeover Losses

After integration, roll materials transfer directly from rotary pre-processing to flatbed precision cutting without manual handling. This eliminates downtime caused by stretching or misalignment, improving continuous production stability—ideal for high-volume roll material processing.

Single-Step Processing for Complex Applications

By combining rotary die cutting for continuous kiss cutting with flatbed die cutting for complex shapes, this integrated solution enables cutting and waste removal in a single, streamlined process—eliminating multiple processing steps.

Precision Synergy for Reduced Error

By combining the continuous feeding of rotary die cutting with the servo positioning of flatbed die cutting, positioning accuracy of within ±0.03 mm can be achieved. This integration overcomes the precision limits of rotary die cutting for complex shapes and eliminates cumulative errors in continuous flatbed processing, making it ideal for high-precision product requirements.

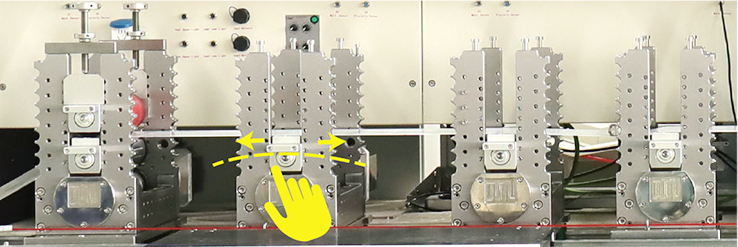

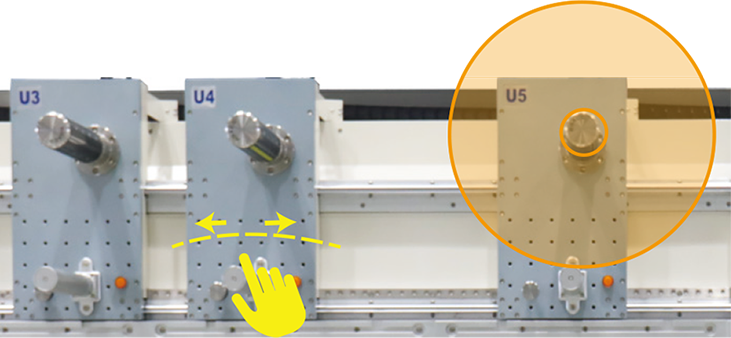

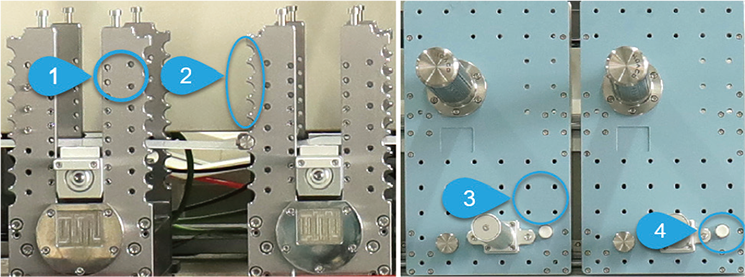

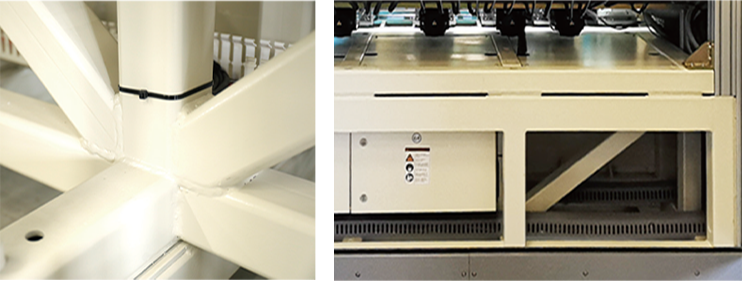

Entire Machine on a Single Base Frameof PWHT Steel

Precision is baramount in RDc stations, demanding meticulous mechanica construc.tion for station-to-station accuracy.Evenslight deformations over time can compro.mise cuting precision. That's why HOAc0 machines are buit on a single unifedPWH(Post Weld Heat Treatment) treated steel base frame, ensuring enduring accura.cy, durability, and repeatability through extendedheavy duty use,Trust in HOAcO forunwavering performance over the long haul.

MECHANICAL ADVANTAGES

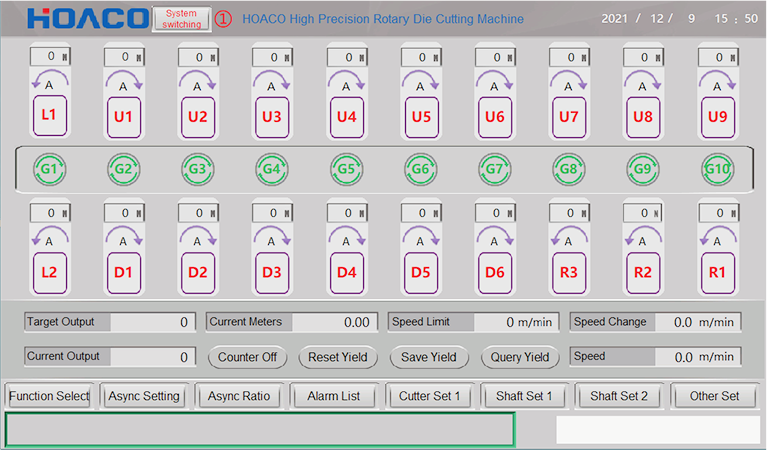

Easy-toUse Touchscreen HMl Console

Configure all settings though intuitive touchscreen

- Main-Home screen showing overall machines status

- Stations-Start/Stop,CW/CCW, Speed Ratio,Sync/Async

- Shafts-Start/Stop,inflate/Deflate,CW/CCW, Alarm Diameter

- FunctionStandard Async, Sensed Async, Cut-to-Mark, Follow, etc

- Others-Gears, Output, Recipe Save/Load

That is about 90% of what you need to learn to operate a HOACO RDCmachinelike a pro, Extra settings will be required only when optionalsystems are in-staled,such as CCD vision system.

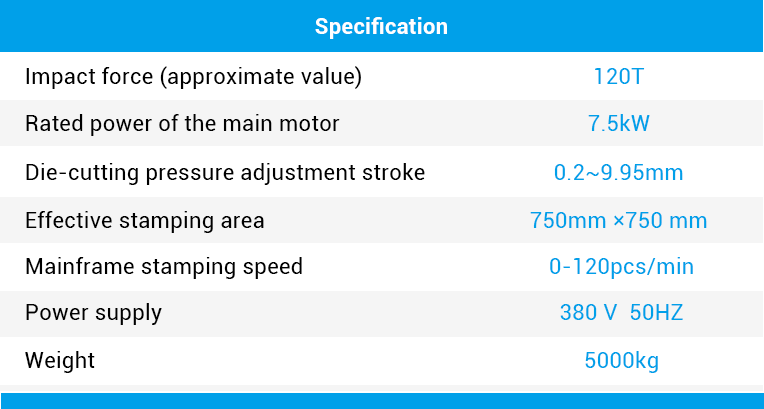

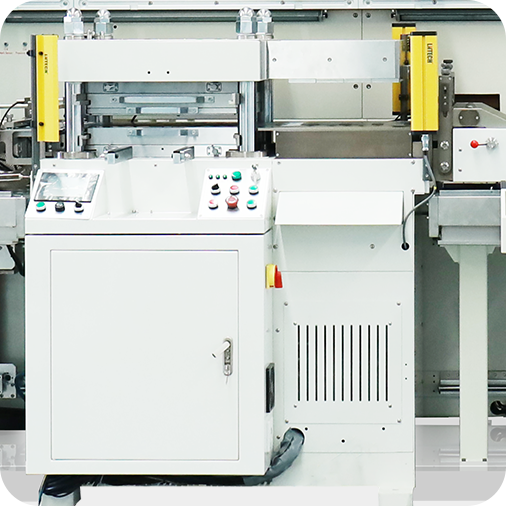

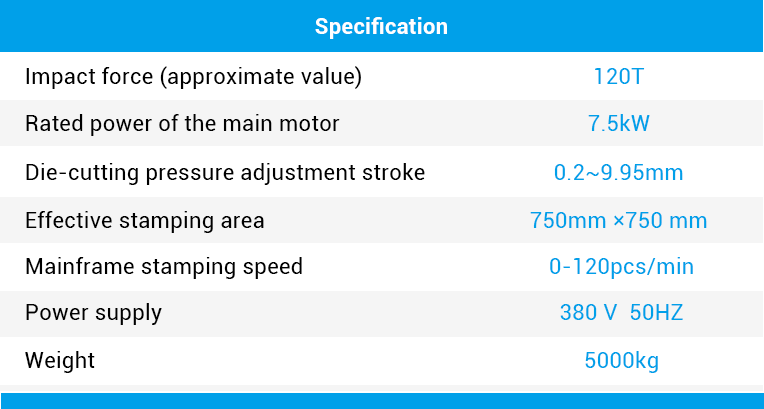

Flatbed Die Cutting Machine

Professional flatbed die cutting equipment designed for high-precision converting applications, offering dependable performance, durability, and operational safety. The machine supports repeatable stamping with a maximum cutting accuracy of ±0.03 mm and enables adjustment-free kiss cutting for consistent product quality.

With a maximum stamping speed of up to 300 spm (HXM-2) or 200 spm (HXM-4), the system delivers high productivity. Standardized tooling and die installation allow fast setup and quick adjustment, minimizing downtime.

The machine is well suited for efficient, high-quality production lines for black and white adhesive products, black light unit products, and similar applications. Overall production output can reach up to 10,000 sheets per hour.

Delivering Innovative Converting Solutions

For Your Most Demanding Challenges

Key Features

- Offers the best of both rotary die cutting and flatbed die cutting in a single machine

- Web buffering system enables RDC operating in continuous mode while flatbed in step mode

- Integrated machine control

- Flexible and easy waste removal

- RDC or flatbed can operate independently when required

- Flexible and easy slug removal