CCD Vision System

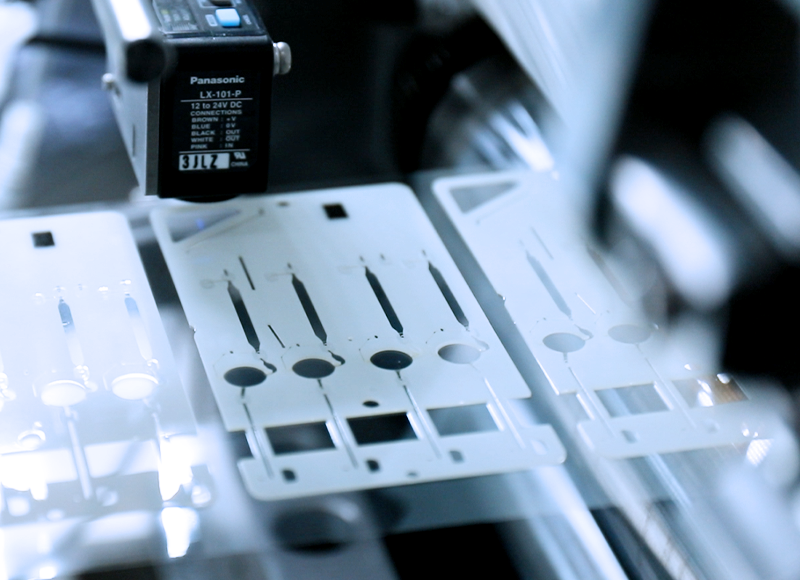

The visual inspection system converts the captured target into an image signal through an image sensor (i.e., an image acquisition device, which is divided into CMOS and CCD types), and transmits it to a dedicated image processing system. Based on the pixel distribution and information such as brightness and color, it is transformed into a digital signal. The image system performs various operations on these signals to screen and detect the features of the target, and controls the on-site equipment actions based on the discrimination results. It is a reliable solution to help users improve production efficiency and product quality.

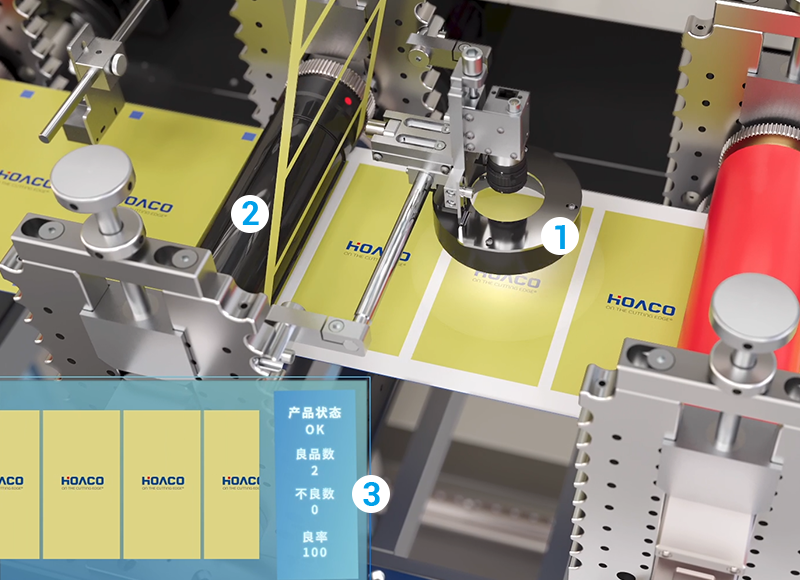

System accessories

1. Image sensor

2. Die-cutting with a knife die

3. Defective product detection

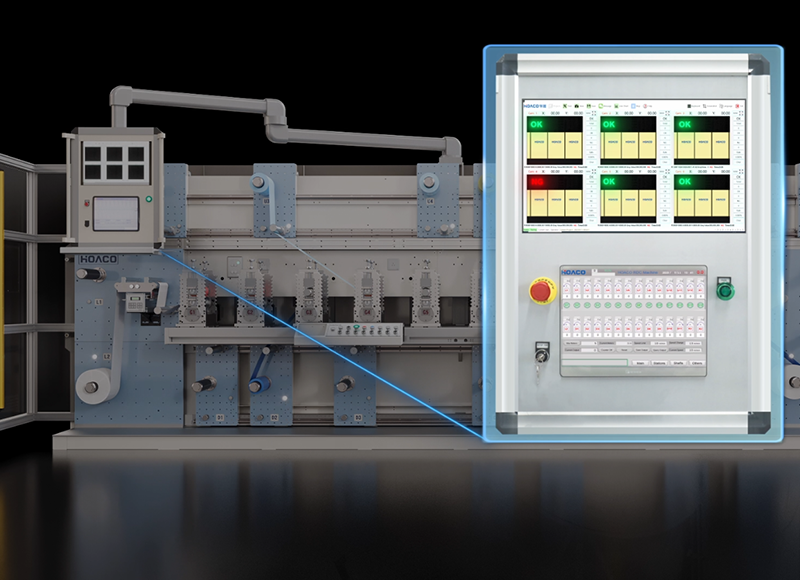

System operation window

Graphical interaction and humanized design The system adopts an intuitive graphical operation interface. The layout of functional buttons conforms to the operation logic, simplifying the processes such as parameter setting and detection startup into clear steps. It is also equipped with real-time prompts, making it simple and easy to operate. The operation window supports multi-dimensional parameter customization. The parameter area can adjust parameters related to detection accuracy and efficiency, adapting to different tasks such as micro-defect detection and size measurement.

Performance characteristics

1. Ready to use immediately

2. Switch the network port at will

3. Convenient to operate

4. Support multi-point measurement

5. Support multiple languages

Customized development of visual software

For specific visual requirements of customers, customized visual software such as VisionPro, VisionMaster, and Halcon can be used. The current customized development functions are as follows: *Image stitching size detection *Line scan size and appearance inspection *Deep learning appearance inspection *Robot mounting

HOACO Vision

Customer-centered, we provide refined services covering pre-sale, in-sale and after-sale