In the advanced energy industry, particularly in the fields of batteries, energy storage systems, and photovoltaic components, core parts—such as electrodes, separators, gaskets, and flexible circuits—require highly precise cutting, forming, and punching processes. Rotary die cutting machines are the key equipment that performs these “precision cutting surgeries.”

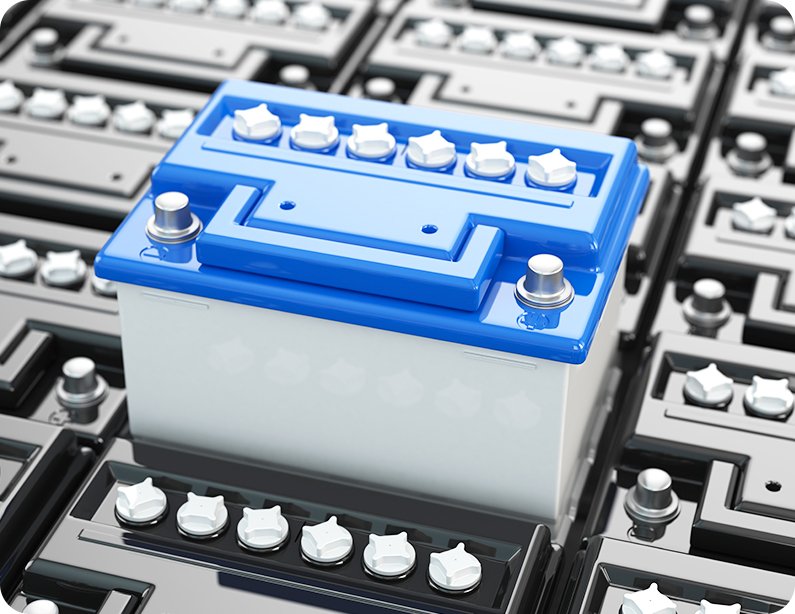

Lithium Battery Manufacturing (Critical Application Area)

Electrode slitting

Tab forming

Separator cutting

Sealing gaskets (top cover / side plate insulation pads)

Conductive / thermal adhesives

In the production of advanced energy EV power batteries and energy storage batteries, rotary die cutting machines handle multiple key processes, including high-precision cutting of lithium battery electrodes and forming of separators.

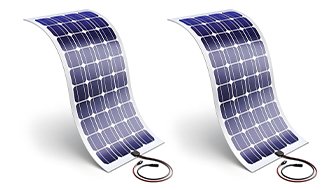

Photovoltaic (PV) Manufacturing

1. Flexible solar cells: For cutting conductive substrates and encapsulation materials for thin-film solar cells.

2. Conductive grids/circuits: For precision die cutting of conductive elements in PV modules.

3. Sealing and insulation materials: Provide various sealing gaskets for PV backplanes and frames.

Other Components for Electric Vehicle (EV)

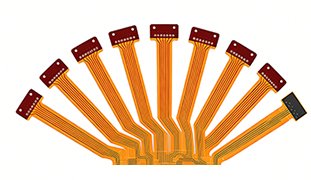

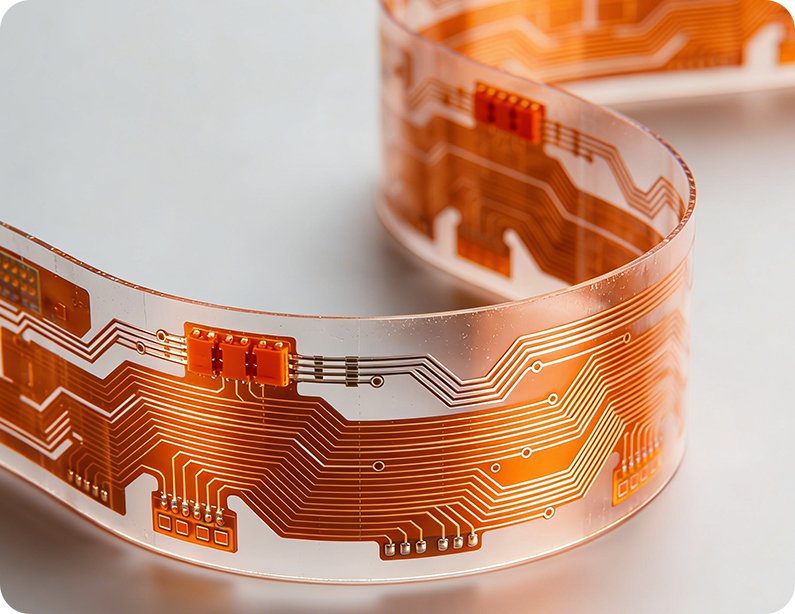

Onboard flexible circuits: Rotary die cutting of FPC flexible boards used in battery management systems, displays, and more.

Acoustic/thermal insulation materials: Die cutting of various lightweight, high-performance materials used throughout the vehicle.