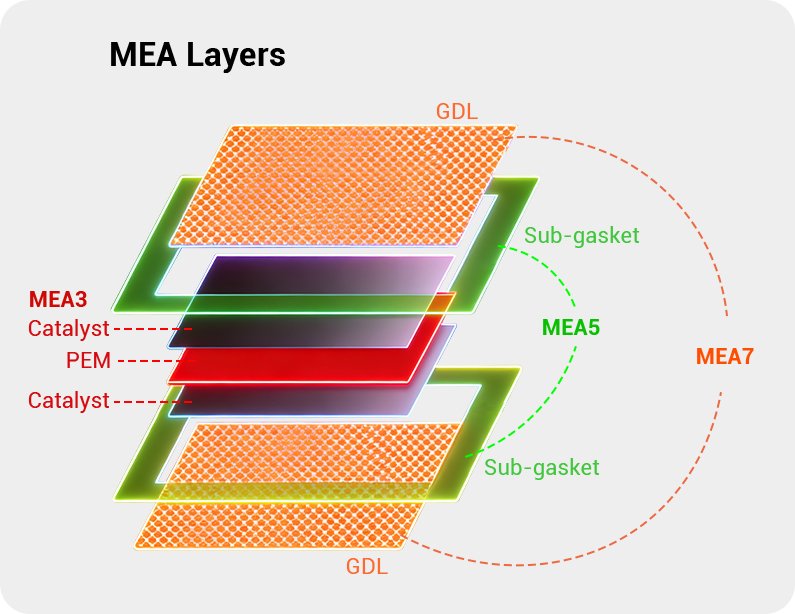

Precision Converting for Fuel Cell MEA

In fuel cell manufacturing, MEA materials are fragile and high in value, making waste reduction and process efficiency critical. HOACO specializes in precision converting solutions that ensure stable, efficient processing while protecting material integrity and minimizing scrap.

High-Accuracy Rotary Die Cutting and Laminating Solutions

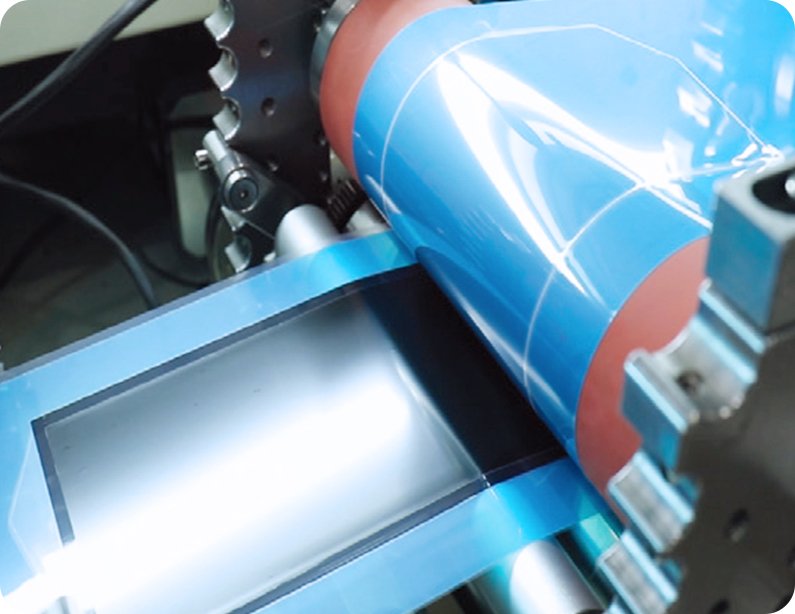

As a core component of PEM fuel cells, the Membrane Electrode Assembly (MEA) requires extremely accurate and repeatable downstream processing. HOACO rotary die cutting and laminating machines are designed for high-precision, high-efficiency MEA converting and assembly, supporting cutting, laminating, layer alignment, and continuous production of all typical MEA layers to achieve consistent quality and optimized material utilization.

RotoMEA3: CCM by Decal Transfer

Converts two rolls of single-side-coated PTFE/PEM into a single roll of double-side-coated PEM (CCM) by heat-assisted decal transfer and lamination. Decal transfer temperature and duration can be accurately controlled to achieve optimal transfer result.

RotoMEA5: Subgasket Attachment

Cutting and laminating top/bottom sub-gasket layers to MEA3 to produce MEA5, RotoMEA5 18-stations model can add double-layer gaskets (top and bottom), while its 26-station counterpart model can attach 4-layers (top2 and bottom 2)- all in a single pass.

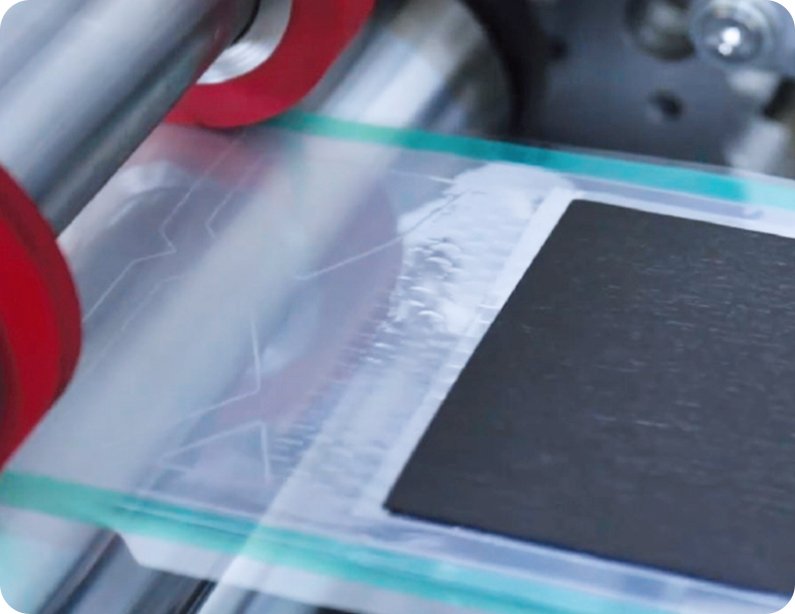

RotoMEA7: GDL Attachment

RotoMEA7 attaches top and bottom GDL layers to produce the final MEA assembly in sheets. Heat rollers are used when necessary to trigger heat-activated adhesive on GDL and improve lamination result.