Being a rotary die cutting equipment supplier, we know better the importance of quality rotary dies than everyone else. Through fully-owned subsidiary companies, HOACO has the full capabilities to design and build all types of high precision rotary solid dies to better serve our customers with stringent quality control and fast turnaround time.

Whenever you engage HOACO for a rotary die cutting solution, you are guaranteed for the best result and precision as we own the complete production cycle from machine to process to rotary dies.

Rotary Tooling

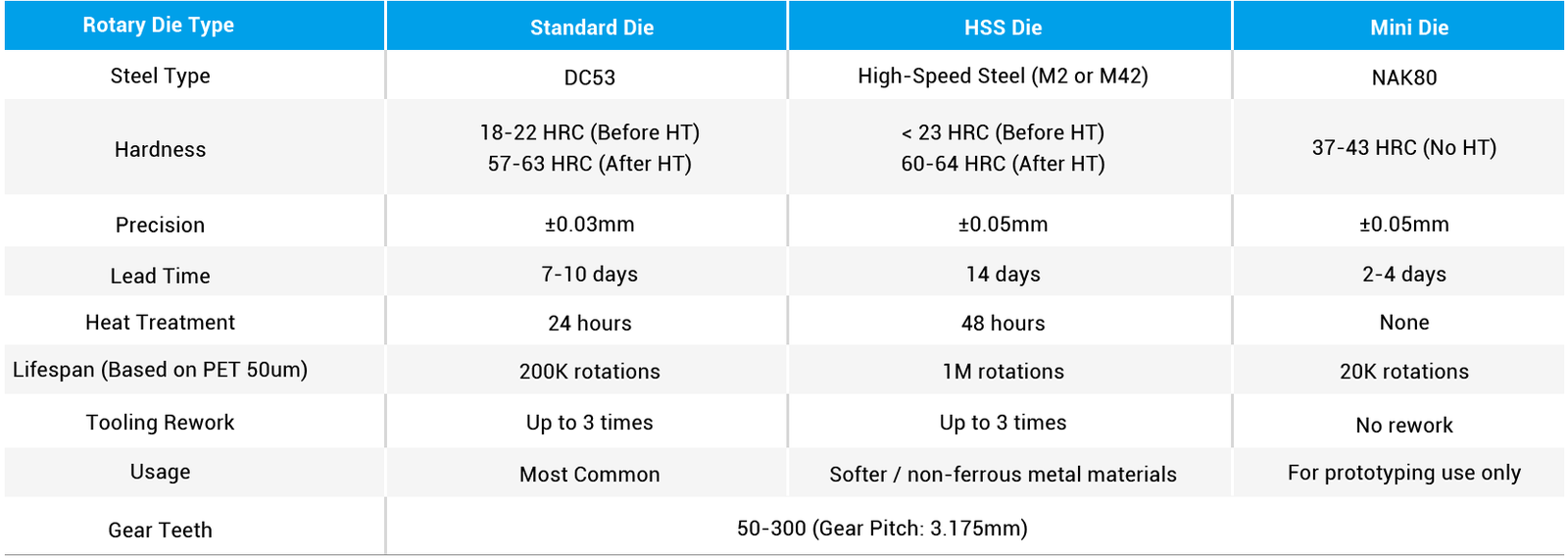

Solid Die

It is widely used for cutting adhesive products, self-adhesive materials, and packaging materials. This type of cutting tool is the foundation of all rotary dies, with other rotary die types developed from it.

Advantages:

High hardness, excellent wear resistance, and long service life

Cutting blade accuracy up to 0.02 mm

Minimum gap between cutting lines as small as 0.3 mm

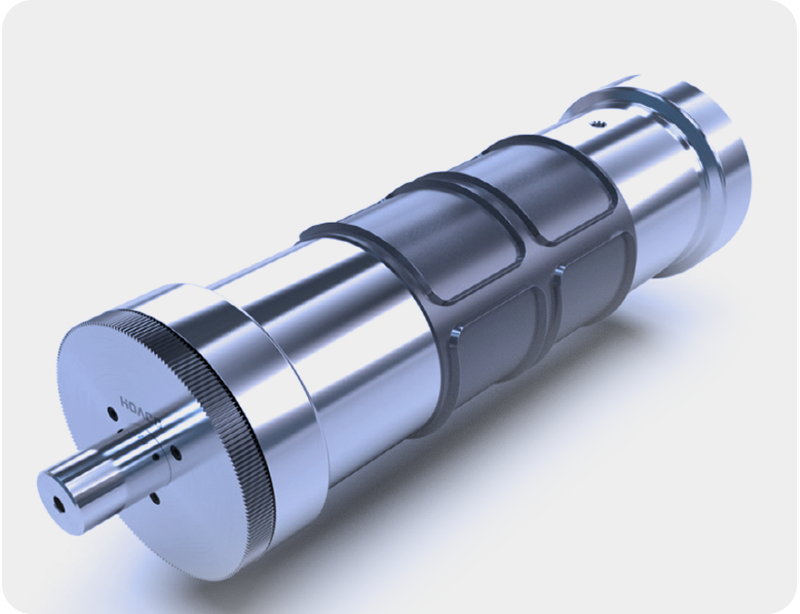

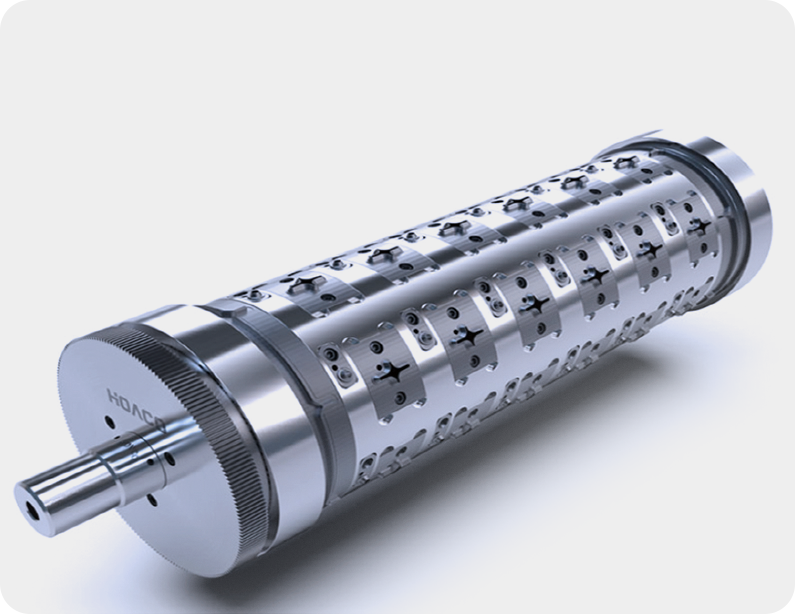

Pin-Eject Die

Holes waste is pushed out by retractable pins and carried away by an underlying tape. No air, no noise, just a clean finish.

Advantage:

Die cutting and waste stripping are performed simultaneously, preventing material buildup

Reduces blade damage and improves overall die-cutting quality

Easy to operate, requies no air source, and noise-free

Ideal for small, intricate patterns that are difficult to strip

Minimum waste vent hole diameter down to 0.6 mm.

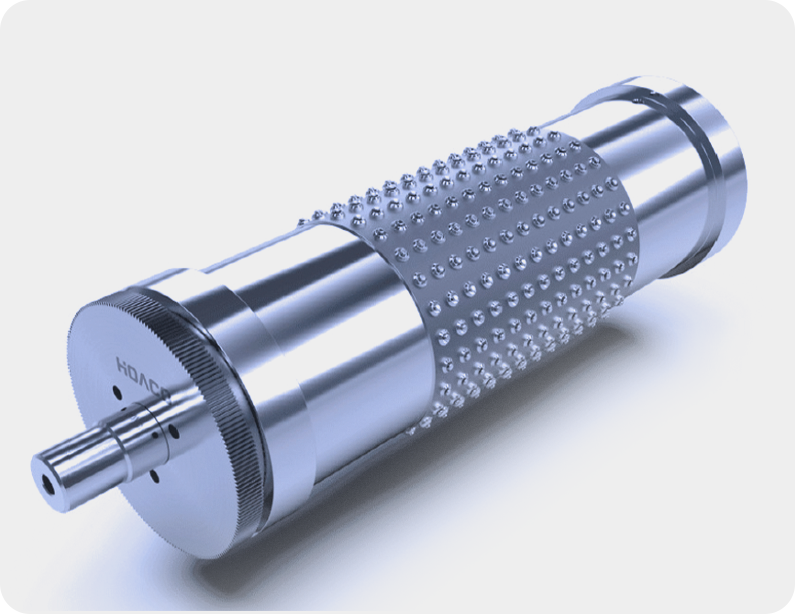

Vacuum Die

Made hollow inside,vacuum dies have through holes on the body to allow waste extracted out by vacuum

Advantages:

The vacuum die draws waste material into the die body.

The waste is then extracted through a vacuum device connected to one end of the die.

This method helps save material.

Effectively reduces blade damage.

Air Eject Die

Air Eject Die Air eject rotary die uses compressed air to assist in the ejection of waste from punched holes.

Advantages:

Use an air-blowing method to remove waste, preventing accumulation in the die cavity.

Effectively reduces blade damage.

Often used together with a waste suction box for more efficient collection of waste.

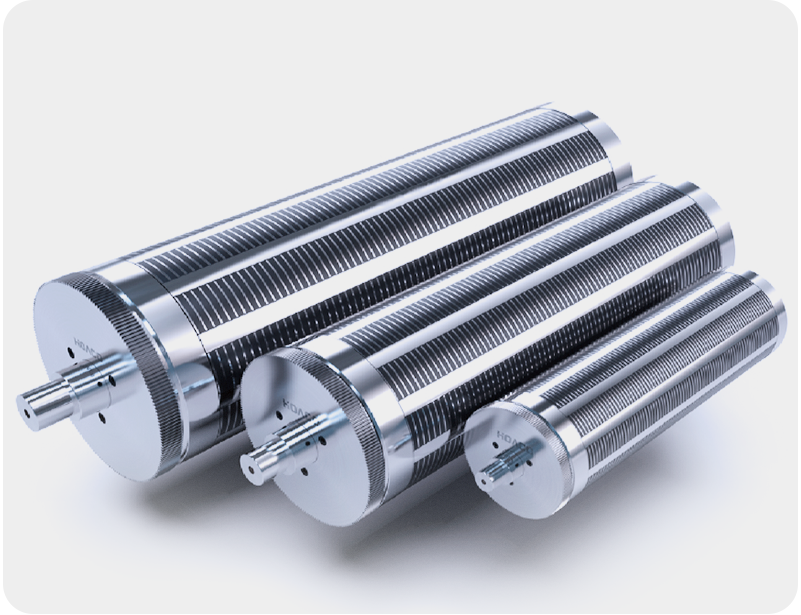

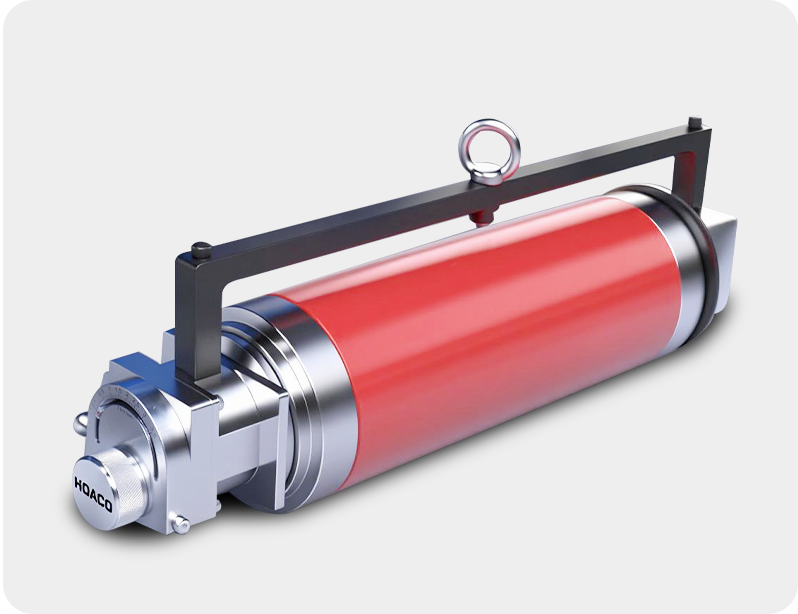

Magnetic Cylinder

The material choice maintains the magnetic force while providing strong and consistent adhesion to the flexible die during usage.

Advantages:

Fine magnetic pole pitch to achieve optimal holding force

Extremely strong holding force for special applications by using neodymium magnets

Dynamic and static micro-balancing

Hardened center positioning for perfect concentricity

Positioning system with adapted bore holes and pins available

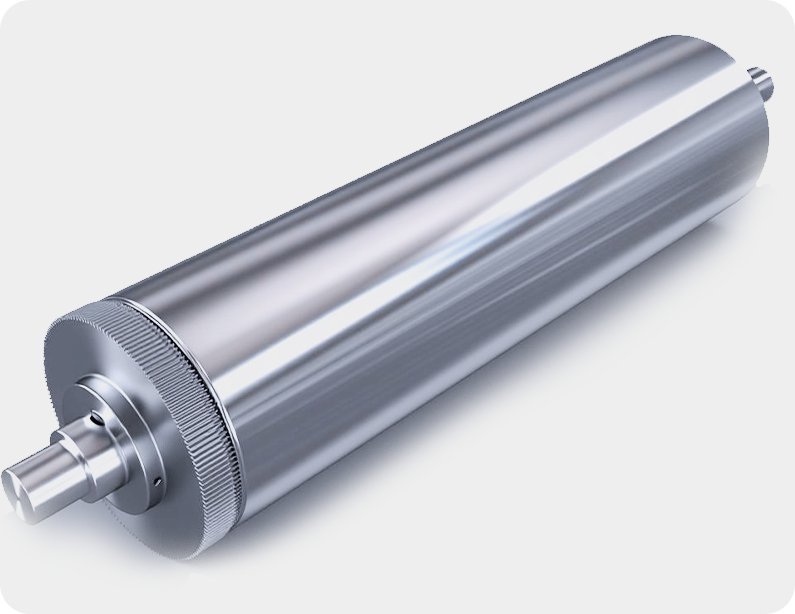

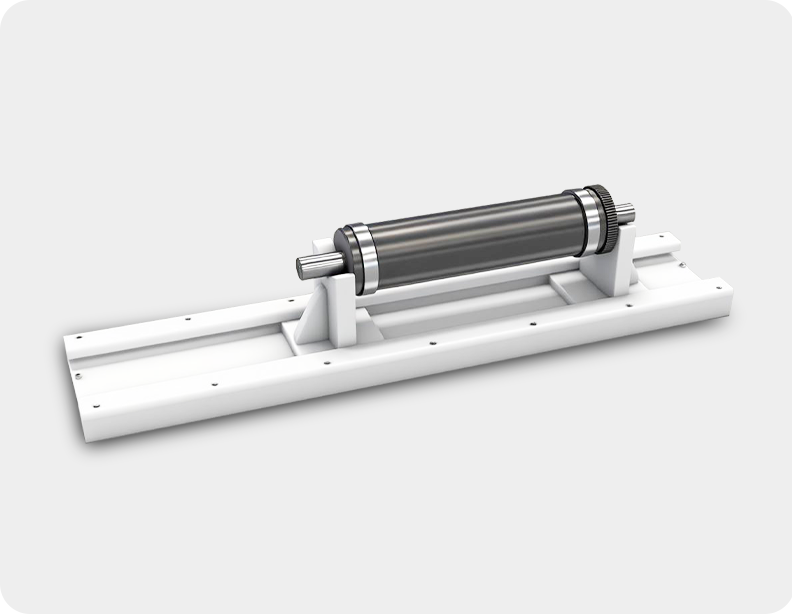

Anvil Rollers

It is a hardened roller with hardness exceeding 62 HRC. lt is constructed from high quality materials to achieve a durable surface, enhancing both performance and service life.

Benefits:

+ Types: Available in plain or stepped (different heights) designs.

+ Application: Suitable for a wide range of converting methods.

+ Plating: Hard chrome plated for superior surface finish and corrosion protection.

+ Key Specifications:Hardness: 62 +/- 2 HRC,Precision: < 3 µm,Cylindricity: < 3 µm.

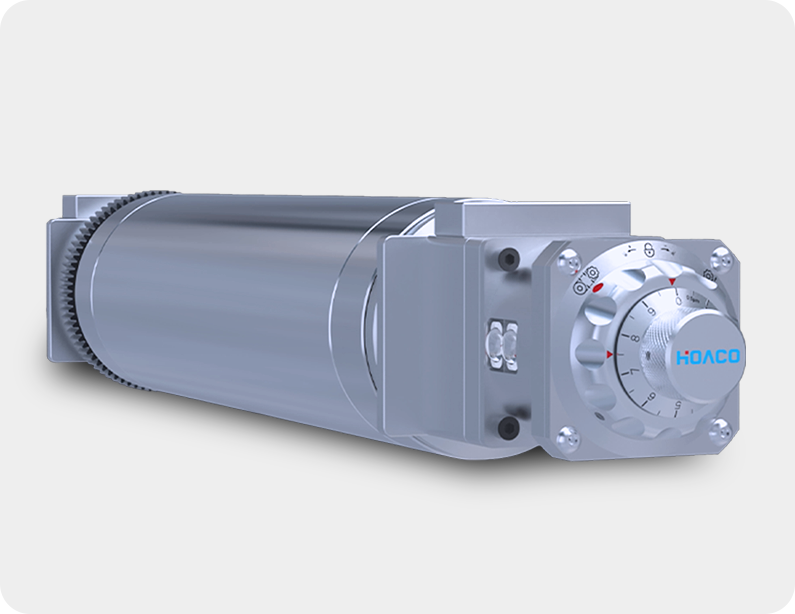

Adjustable Anvil Roller (FlexiAnvil™)

As a key component of rotary die cutting machines, the adjustable anvil roller integrates high-precision adjustment capability with optimized structural design. Its parameters and features directly determine adaptability and operational stability across diverse applications.

Advantage:

Built-in reduction mechanism enables micron-level height control, with a minimum adjustment increment of 0.0005 mm.

Icon-based indicators ensure intuitive operation, while fully built-in adjustment components prevent accidental interference.

Compatible with standard anvil roller dimensions, allowing direct installation without machine modification and minimizing downtime.

Floating connection design maintains constant gear center distance during adjustment, reducing noise and wear while ensuring long-term stability.

Adjustable Nip Rollers (FlexiNip)

The adjustable rubber roller can adjust the gap between the roller body and the bottom roller to meet the laminating requirements of different materials and thicknesses for various application scenarios.

Advantage:

+ Precise matching and flexible adaptation.

+ Adjustable gap for versatile application.

+ Parametric adjustment for flexible production.

+ One machine, multiple uses with high-efficiency compatibility.

Tooling Stand

Used for die tooling storage to protect the blades from damage.

Advantage:

Material: Acrylic, ensuring safety and reliability.

Adjustable positioning according to die length.

Protect the die blades from damage.

.

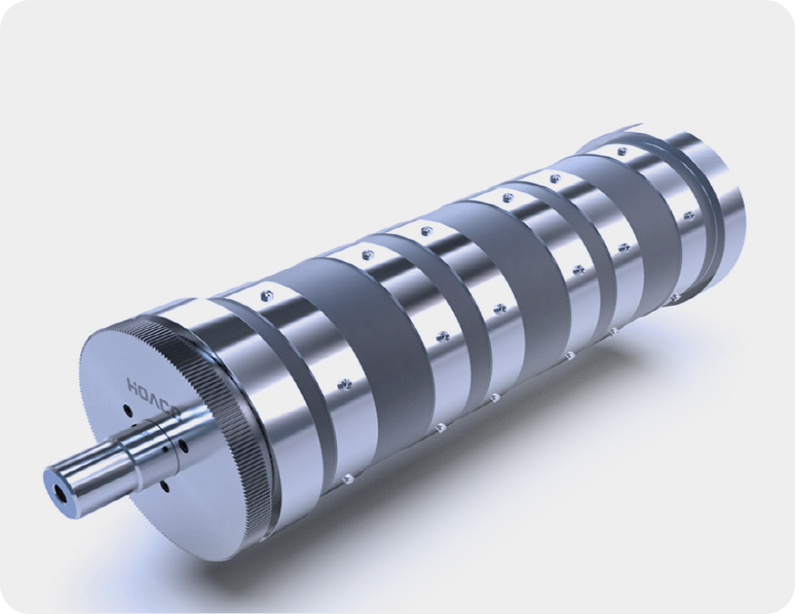

Technical Specifications