Flat Screen Printing

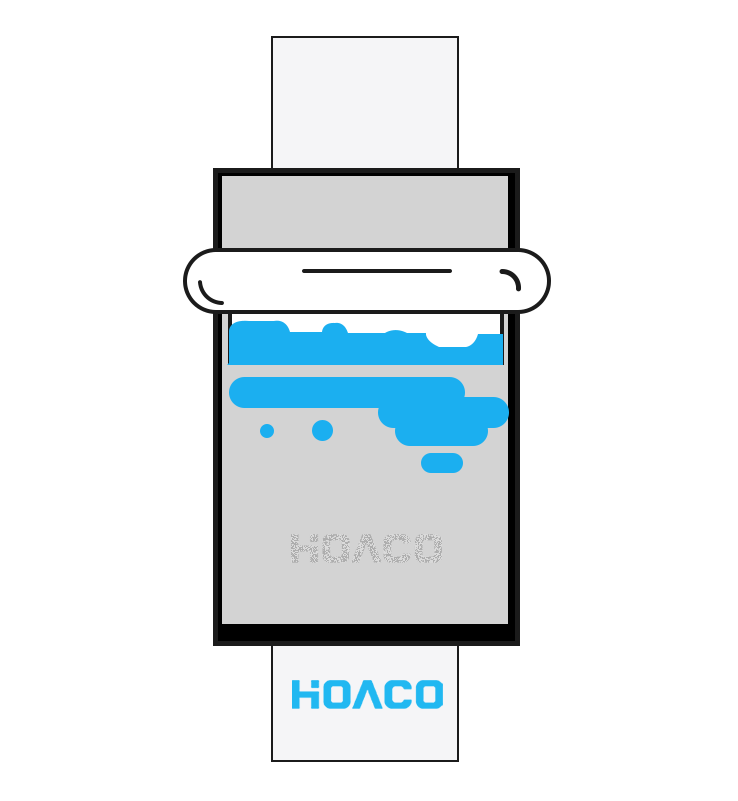

Flat screen printing uses a mesh screen as the printing plate. Through a photosensitive plate-making process, a screen stencil with images and text is created. Screen printing consists of five key elements: the screen stencil, squeegee, ink, printing table, and substrate. The printing principle is based on the fact that ink can pass through the open mesh areas of the image while the non-image areas block ink flow. During printing, ink is poured onto one end of the screen. A squeegee applies pressure and moves at a uniform speed across the screen, forcing the ink through the image areas of the mesh and onto the substrate.

Key Features

Continuous printing with flat screen moving in sync with the underlying substrate web

Medium-speed throughput and precision

Supports UV ink or Solvent ink

Low cost of ownership and maintenance

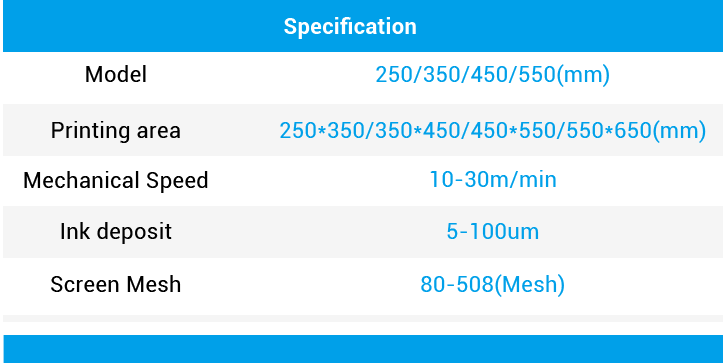

*Other non-standard models can be customized according to the user’s requirements

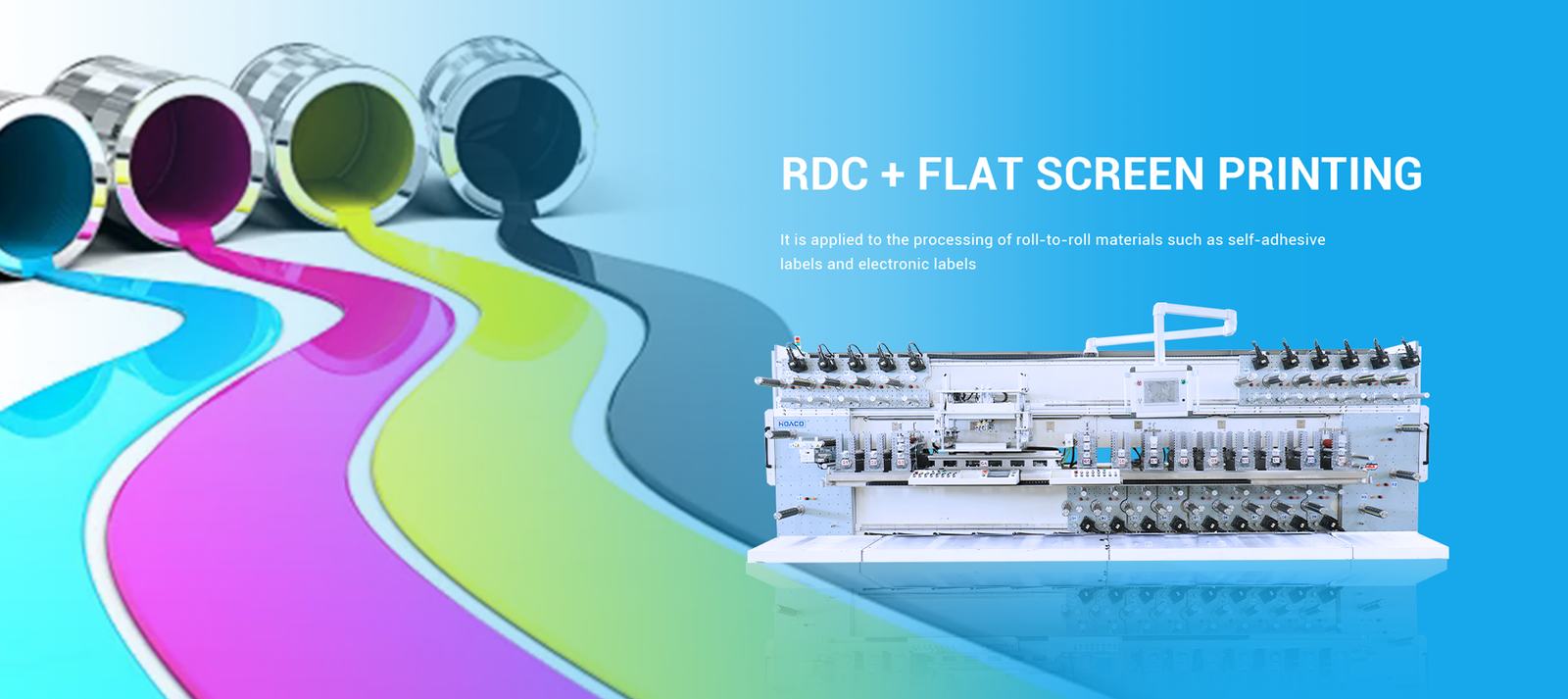

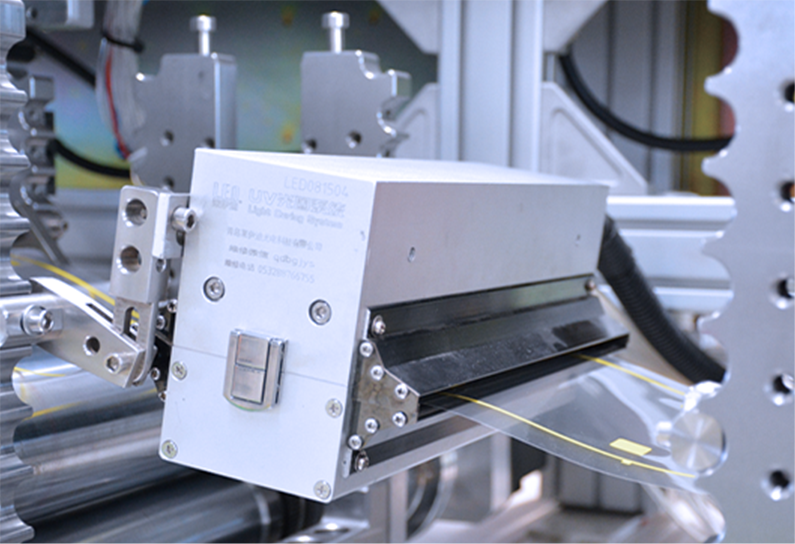

Continuous Flat Screen Printing Integration

The flat screen printing unit operates in a synchronized, follow-up mode and can be directly integrated onto the rotary die cutting platform. This enables continuous printing and cutting in a single process, simplifying workflow and allowing real-time quality monitoring.

High Precision and Mature Technology

Flat screen printing delivers high printing accuracy with tolerances as tight as ±0.05 mm. As one of the most established and widely adopted printing technologies worldwide, it offers proven stability, consistency, and reliability.

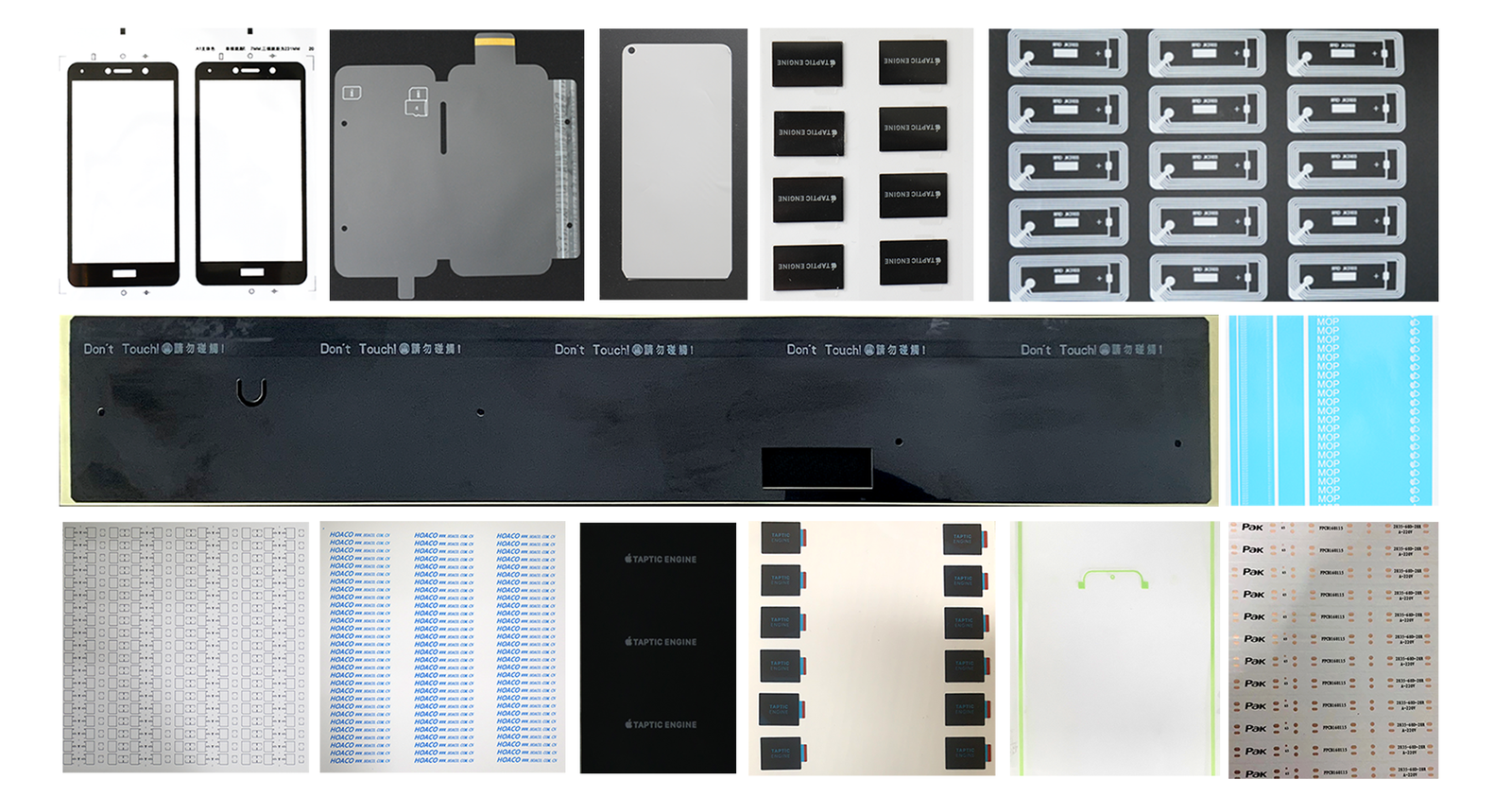

Cost-Effective and Material Versatile

With short screen-making lead times and low tooling costs, flat screen printing is highly economical. It is suitable for a wide range of roll-to-roll materials, making it ideal for diverse products and frequent job changes.

Easy Operation and Flexible Configuration

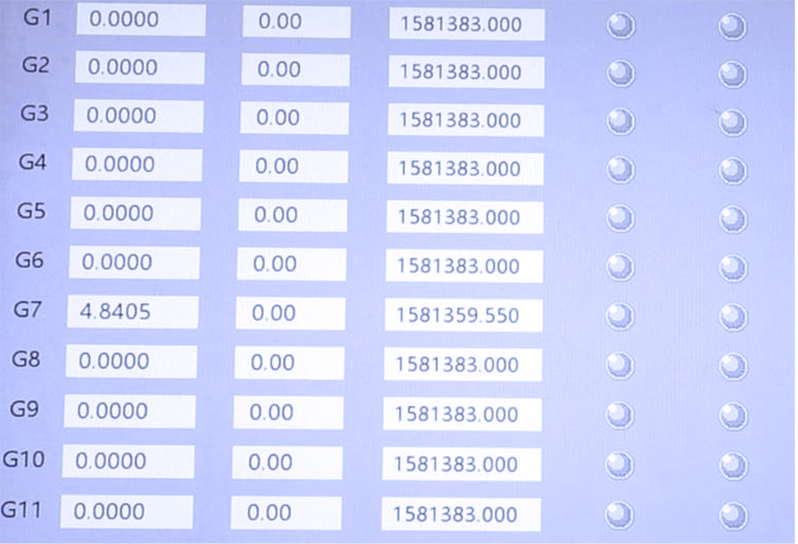

The printing principle is simple and easy to master, requiring minimal training. Screen cleaning and replacement are fast and efficient. The unit can be installed at any station of a multi-station rotary die cutting machine and features an intuitive, independently controlled touchscreen interface with one-touch operation.

Rich Print Quality with Advanced Ink and Curing Systems

Flat screen printing produces thick ink layers with high color saturation, strong adhesion, and excellent light resistance, often eliminating the need for additional lamination. The system supports UV, solvent-based, and water-based inks, and can be equipped with LED UV curing for cold curing, low energy consumption, long service life, and fully automated, synchronized operation.