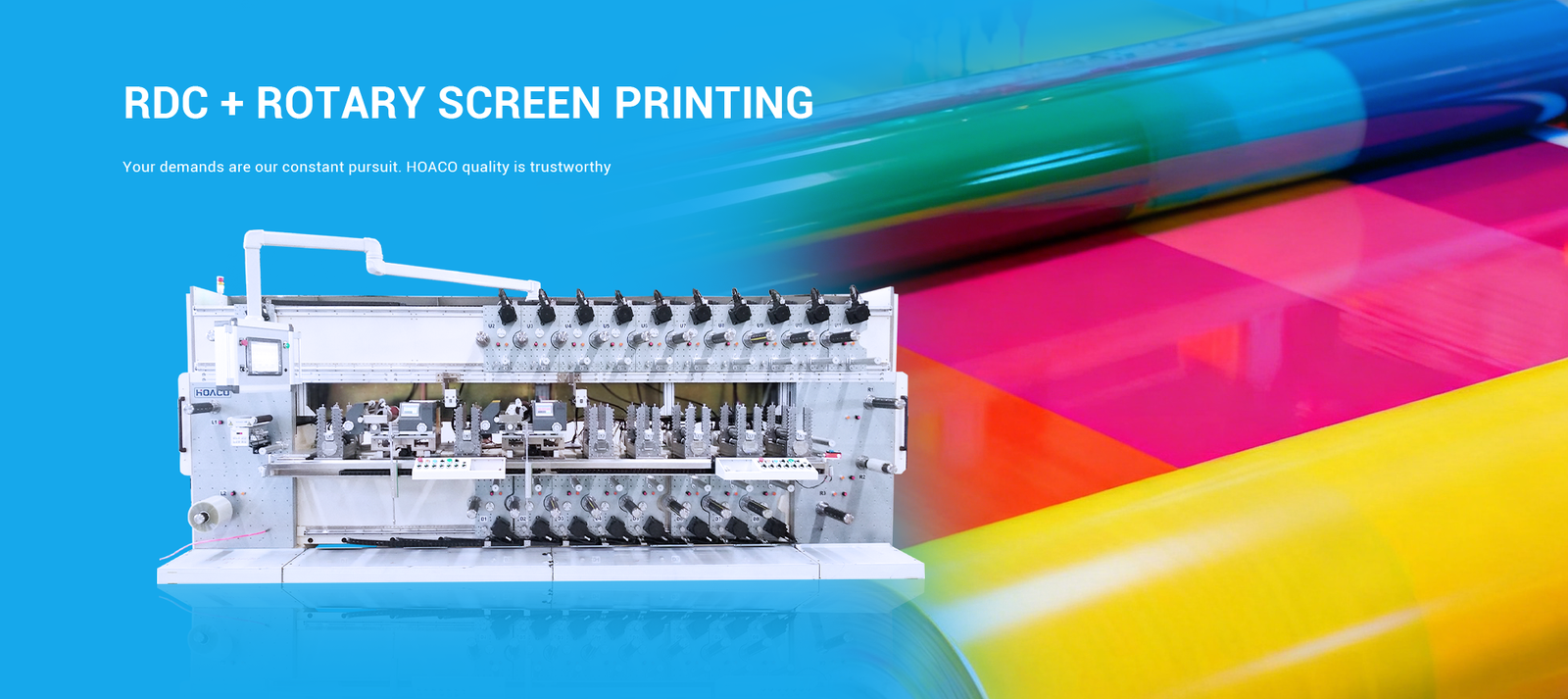

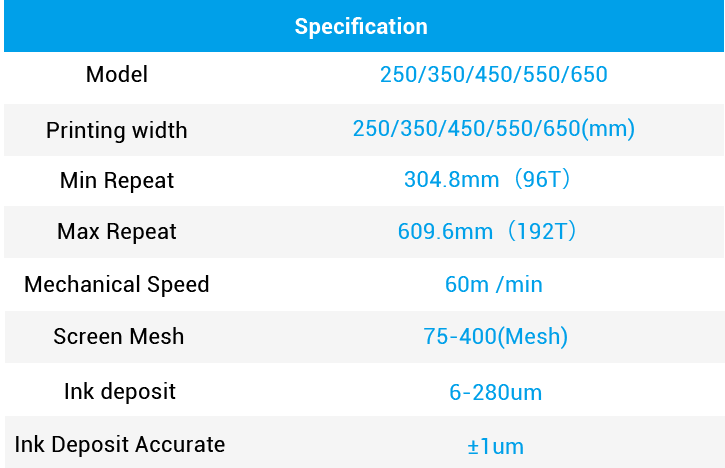

RDC + Rotary Screen Printing Machines

Rotary screen printing machines achieve unique effects that cannot be realized by flexographic, offset or gravure printing processes by obtaining thick ink layers or varnishes in a single print.

Key Features

- Integrated RDC + rotary screen printing system that simplifies process steps and reduces material waste

- High-speed, continuous printing capability

- Movable printing units can be installed between any RDC stations to meet specific process requirements

- Multi-color printing enabled by adding additional printing units

- Optional corona treater for surface treatment

- Supports web widths from 250 mm to 1000 mm

- Integrated central control console

*All screen printing units with printing width less than 1500mm can be customized according to customer requirements

Rotary Screen Printing Process Overview

Rotary Screen Printing is a stencil process where a cylindrical screen containing the image rotates in a fixed position. As the web moves between the screen and the impression roller, screen’s motion forces the ink through the stencil openings onto the substrate through a squeegee.

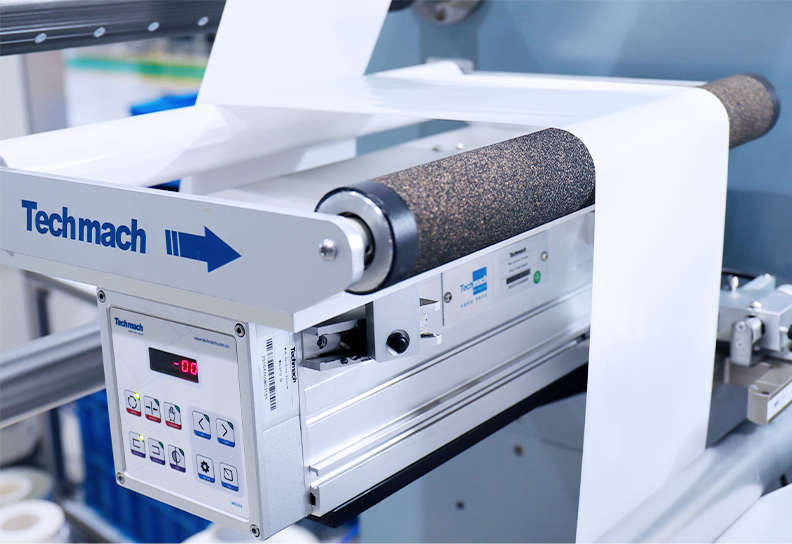

Corona Processor

The corona processor effectively removes surface contaminants from plastic films and increases surface energy. This treatment significantly improves ink printability and lamination bonding strength by enhancing the penetration and adhesion of inks and adhesives on plastic film substrates.

Rotary Screen Printing Unit

- Rotary screen printing is an ideal solution for labels with special effects and is widely used in food, beverage, personal care, and pharmaceutical applications.

- The unit offers long service life, easy installation, and high productivity, with full integration to a servo-driven main machine and intuitive touchscreen control.

- The screen emulsion layer can be fully stripped and re-coated for reuse up to 10–20 times, significantly reducing operating costs.

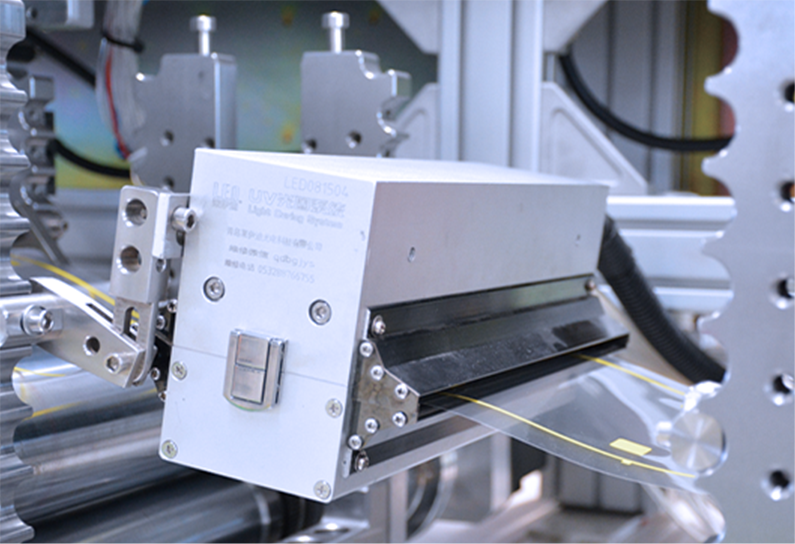

UV LED Curing Light

- UV LED curing uses a cold light source, making it suitable for heat-sensitive materials while preventing deformation and discoloration. It is mercury-free, ozone-free, and environmentally friendly.

- The system delivers instant full output with over 90% energy savings compared to conventional UV lamps. Its compact, low-maintenance design offers a long service life of 25,000–30,000 hours.

- Fully integrated with printing and rotary die cutting machines, the UV LED system automatically adjusts curing intensity based on machine speed and shuts off when the machine stops, enabling efficient and automated operation.

UV Ink

- UV ink is solvent-free with 100% solid content, offering low environmental impact and safe operation. It enables high-precision printing without screen clogging and provides a stable, high-gloss ink film with excellent resistance to abrasion, water, oil, and solvents.

- Instant curing supports high-speed production and higher efficiency. Compared with conventional inks, UV ink is more stable, non-flammable, and easy to transport as general cargo.